3105 H14/H16/H18 Aluminum Closure Sheet For Screw Caps

3105 aluminum closure sheet is a typical rust-resistant aluminum with excellent corrosion resistance, making it suitable for screw caps exposed to liquids for extended periods. The deep-drawing properties make 3105 aluminum sheet suitable for stamping complex bottle cap shapes, resisting cracking or creases. Cold work hardening (such as in H14, H16 and H18 tempers) increases its strength and meets the sealing requirements of bottle caps.

3105 H14/H16/H18 aluminum closure sheet all belong to the Al-Mn alloy family and are commonly used in screw caps. While they share the same alloy composition, they undergo varying degrees of cold work hardening, resulting in varying performance. The following describes them in detail:

- 3105 H14 aluminum closure sheet:

Features medium hardness and good deformation resistance. Its moderate degree of cold work hardening ensures a certain level of strength while maintaining good plasticity and machinability. It is suitable for applications requiring high strength and stability, meeting the production requirements of typical screw bottle caps and is less susceptible to severe deformation or cracking during processing.

- 3105 H16 aluminum closure sheet:

Exhibits a higher degree of cold work hardening than H14, resulting in greater hardness and strength. While maintaining high strength, it also maintains a certain degree of toughness, capable of withstanding greater forces and torques. It is suitable for screw caps requiring high sealing and anti-theft performance. For example, bottle caps for high-end liquors and pharmaceuticals require a superior seal to ensure product quality, and 3105 h16 aluminum sheet is a suitable choice.

- 3105 H18 aluminum closure sheet:

Exhibits the highest degree of cold work hardening of the three grades, achieving high levels of hardness and strength, and possessing strong resistance to deformation and wear. 3105 h18 aluminum sheet can be used in applications requiring extremely demanding bottle cap performance, such as those requiring extreme torque or superior anti-theft performance.

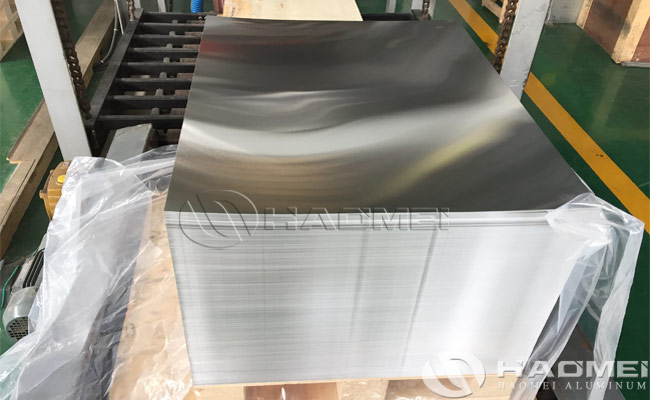

Specifications of 3105 Aluminum For Caps:

- Thickness: Typically 0.15-0.27mm (common range for deep-drawn bottle caps), thicker or thinner thicknesses can be customized upon request.

- Width: 330-1000mm (adjustable depending on production equipment).

- Length: Customizable, commonly available in coils or sheets.

Advantages for 3105 aluminum For Screw Caps Manufacturing:

- Good Sealing:

3105 H14/H16/H18 aluminum closure sheet exhibits excellent ductility and flexibility. When formed into threaded caps, it fits snugly against the bottle opening, creating a strong seal that effectively prevents liquid leakage and the ingress of air and impurities.

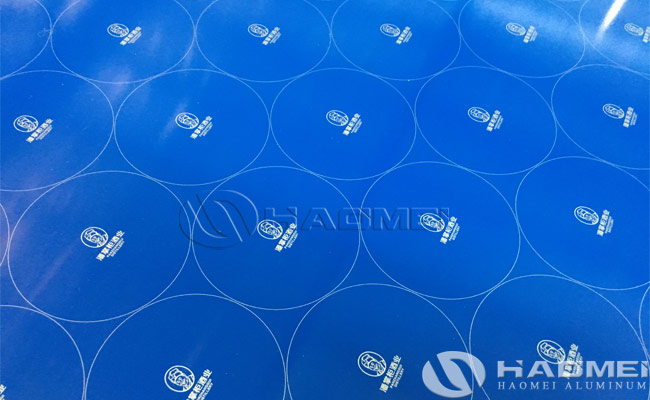

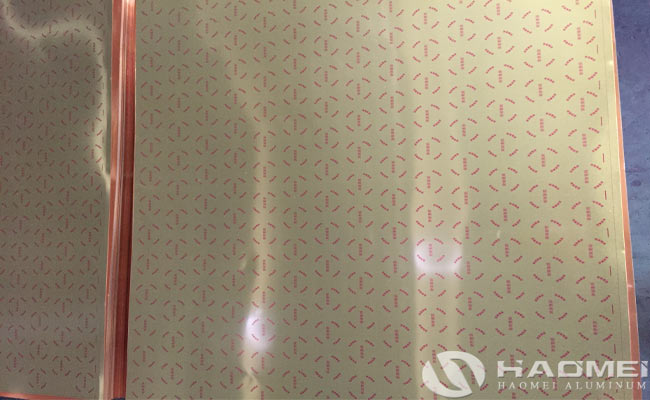

- Aesthetic Appearance:

Aluminum sheet has a smooth surface and uniform color. After processing and treatment, it can be created with a variety of exquisite designs and patterns to meet the packaging needs of different products and enhance the overall product image.

- Strong Anti-Counterfeiting:

Aluminum caps can incorporate a variety of anti-counterfeiting technologies, such as laser marking, embossing, and special coatings, making it more difficult to produce counterfeit and substandard products, protecting the interests of consumers and businesses.

- Suitable for Automated Production:

3105 H14/H16 aluminum sheet's strength, elongation, and processing properties meet the requirements of highly automated bottle cap production processes. It can adapt to automated production processes such as high-speed stamping and spinning, improving production efficiency and reducing production costs.

- Good Food Safety:

3105 aluminum alloy offers excellent food safety, cleanliness, and hygienic safety, meeting the stringent packaging material requirements of the food, beverage, and pharmaceutical industries, without contaminating the contents.

Applicable Applications of Aluminum Screw Caps Made From 3105 Aluminum Closure Sheet:

- Food and Beverage Caps: Such as mineral water and carbonated beverage caps (requiring tamper-evident design).

- Pharmaceutical/Cosmetic Caps: Require sealing and corrosion resistance.

- Industrial Chemical Caps: Require high corrosion resistance.

3105 aluminum closure sheet, due to its high corrosion resistance, excellent deep-drawing properties, and customizable processing, is an ideal material for screw caps. Whether in the food and beverage, pharmaceutical, or industrial chemical sectors, 3105 aluminum sheet meets the sealing, durability, and aesthetic demands of bottle caps.