3105 Aluminum Closure Sheet For ROPP Caps

In the metal packaging industry, ROPP (Roll-On Pilfer Proof) caps are a core component of wine, beverage, and pharmaceutical packaging. The choice of material directly determines sealing performance, processing efficiency, and product lifespan. Having worked in aluminum sheet production and R&D for thirteen years, the most demanding requirements I've encountered come from the ROPP cap industry—these screw-on tamper-evident caps, while seemingly simple, actually require more than ten processes, including cup-making, stretching, engraving, thread rolling, and edge curling. They must also withstand the internal pressure of carbonated beverages, the corrosion of alcoholic beverages, and high-temperature sterilization. After trying 1060 pure aluminum and 8011 alloy, 3105 aluminum closure sheet ultimately became the industry consensus for ROPP caps.

The two most critical indicators for ROPP bottle caps are: first, the threads must not deform after forming; and second, the tamper-evident ring must break precisely when screwed on. This requires the aluminum sheet to have sufficient strength without being too brittle. 3105 is an aluminum-manganese-magnesium alloy. During production, we control the manganese content to 0.3-0.8% and the magnesium content to a stable 0.2-0.8%. The reinforcing phase formed by these two elements allows the aluminum sheet to achieve a tensile strength of 130-180 MPa after cold working (H14/H16 temper), perfectly matching the pressure requirements during thread forming.

A comparison makes this clear: 1060 pure aluminum has too low strength, making it prone to deformation under internal pressure when used for carbonated beverage bottle caps; while 8011 alloy has good formability, its strength is insufficient, causing thread collapse when stacked in a storage box. Our 3105 aluminum sheet undergoes multiple cold rolling processes, resulting in a yield strength consistently above 115 MPa. Last year, tests conducted for a well-known carbonated beverage factory showed that after sterilizing 5000 bottle caps at 120℃, the thread perpendicularity error was consistently within 0.02 mm, far below the industry standard of 0.05 mm.

ROPP caps production is a high-speed automated operation, punching hundreds of caps per minute. During deep drawing, insufficient ductility of the aluminum sheet can easily lead to cracking at the bottom or wrinkling on the sides. 3105 aluminum sheet for ROPP caps, with an aluminum content as high as 98%, inherently possesses excellent plasticity. In the annealing process, we precisely control the temperature at 344℃, ensuring the grain size remains stable between 80-100μm. This grain size range guarantees uniform deformation during deep drawing without causing orange peel texture on the surface due to excessively large grains. A customer who previously switched to another supplier's 3105 aluminum sheet experienced a 15% scrap rate during deep drawing; after switching to our product, the scrap rate dropped to 0.3%. The key lies in our continuous casting and rolling process, which reduces alloy segregation and ensures that the elongation of each coil of aluminum sheet remains consistently above 4%, allowing even complex, irregularly shaped bottle caps to be formed in a single step.

Bottle caps come into direct contact with food and beverages, so corrosion resistance is paramount. 3105 aluminum sheets naturally form a 5-10μm protective alumina film in the air. We further treat this film with chromate phosphate to make it denser, preventing corrosion spots even when filled with acidic juices or high-proof spirits. Last year, we conducted an accelerated aging test, immersing our 3105 aluminum caps in 45℃ vinegar for 30 days; the surface remained shiny and rust-free afterward.

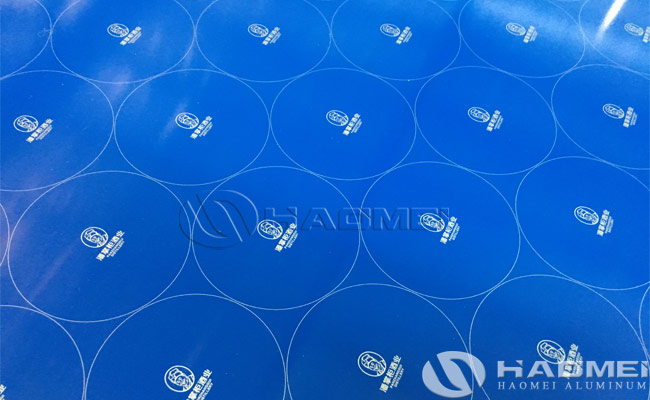

For brand owners, the appearance of the bottle caps is equally important. Our 3105 aluminum sheets have a surface roughness controlled to below Ra0.2μm, resulting in ink adhesion 30% higher than the industry average. Our customers' gold laser-etched bottle caps showed no paint peeling even after 2000 rubbing tests. This is thanks to our four-roll cold rolling mill, which effectively eliminates surface scratches, ensuring a surface flatness error of less than 2mm/m for each roll of aluminum sheet.

Making aluminum sheets isn't about specifications, but about stability. We have our own spectral testing laboratory; every batch of raw materials undergoes compositional analysis, and every roll of finished product is tested for mechanical properties, all to ensure the stable operation of our customers' production lines. Over the years, bottle cap factories that have cooperated with us have all said that using our 3105 aluminum closure sheets has significantly reduced the failure rate of bottle cap machines—this is probably the result that our technicians most want to see.